It becomes humanly difficult to run high capacity boiler by burning more fuel manually. Hence one can attain upto 400 kg/mt2 /hr Fuel combustion. The range of the boiler can be from 3-tons onwards.

Increase in the fuel costs has forced Industries to look for cheaper alternative fuels. India being an agricultural nation, has a lot of agrofuels like Rice Husk, Ground Husk, Bagasse etc.

Qucon has the necessary expertise and experience to burn these agro fuels efficiently. These agro fuels are available for only 6 to 9-months in a year so there is a requirement for a firing system

suitable for conventional fuels like coal, wood, oil, natural gas as well. In some industries, there is a need to fire byproducts like biogas.

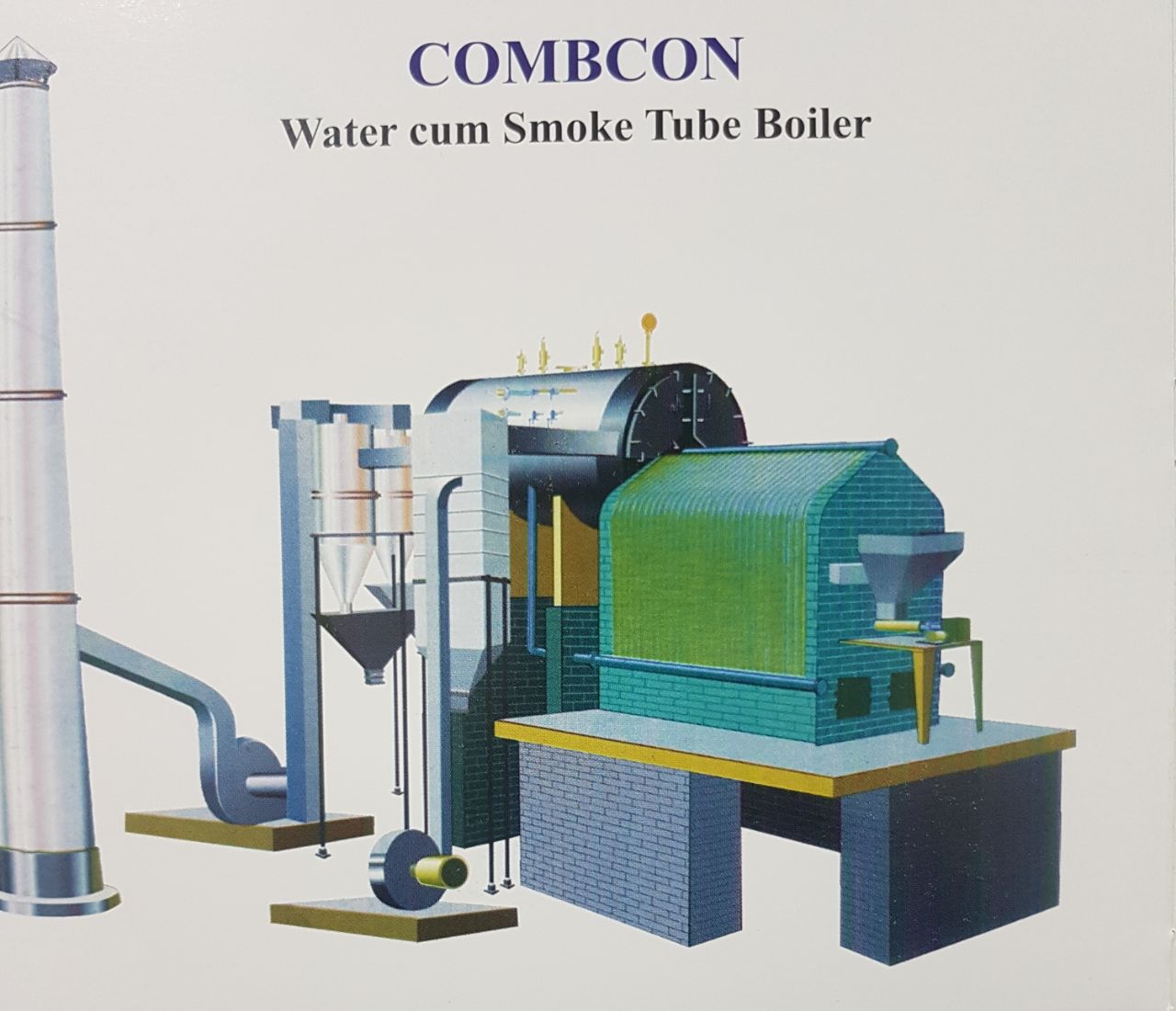

Rice husk, Crushed Coal & Wood palette's address these scenarios using a systematic product development process and have come up with the perfect solution "COMBCON BOILER".

For efficient combustion of these fuels, the furnace temperature plays an important role. The furnace designs are chosen with adequate "Time, Temperature & Turbulance" for efficient burning of fuel. This results in

- 1. Consistent output

- 2. Less Furnace cleaning

- 3. Multiffuel capability

- 4. Efficient combustion

What COMBCON offers

- Uninterrupted dry steam at rated pressure

- Fuel flexibility

- Agro fuel firing possibility

- Conventional fuel like Coal and Rice husk

- Lower fuel bills due to high thermal efficiency

- Thermal efficiency 82% on GCV for conventional fuels like Crushed Coal

- Thermal efficiency 80% on GCV for agro based fuels

- Thermal efficiency 88% on NCV for oil, Natural Gas and Bio-gas

- Less time needed for erection and commissioning

- Easy access to boiler parts for cleaning and maintenance

- Adequately designed ash settling chamber in furnace ensures the lowest ash carryover which results in lower erosion

- High water holdup and adequate steam space gives sufficient thermal inertia for responding to fluctuating loads

- Low consumed power

SPECIAL FEATURES

- Qucon Boilers are designed to the latest international / IBR code & are Provided with more than all mandatory safety requirements.

- High overall efficiency combined with reliable operation is achieved through Accurate CAD thermal design of the boilers.

- Large water holding capacity of boiler can meet fluctuating steam load.

- Gas & water side accessibility will reduce maintenance "down time".

- Consistent & trouble free performance under "Normal Op. Conditions".

- Minimum refractory, very less cost of maintenance.

- Multi-Fuel adaptability by selecting appropriate Combustion equipment.

- Large disengaging surface & free board distance in boiler ensures high purity Up to 98% dry saturated steam under adverse operating conditions.

- Glass wool / Mineral-Wool insulation with rigid steel cladding provides High insulation & does not get damaged like aluminum cladded surface.

CONSTRUCTION

- Pr.& non Pr.Parts both are ruggedly constructed to meet most adverse operating conditions in boilers house.